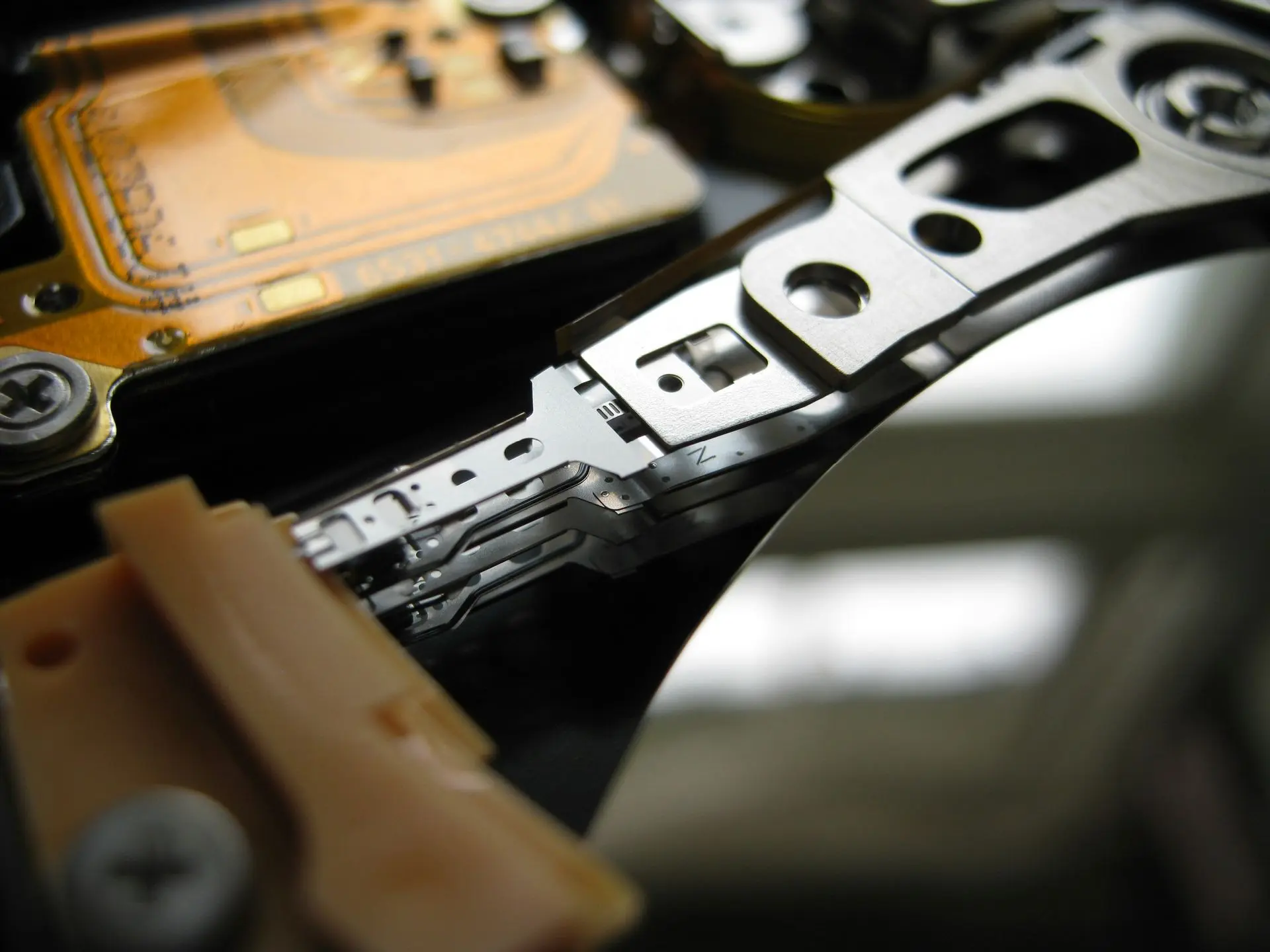

Bayonet temperature probes

A firm and quick hold for demanding environments.

With their bayonet fastening system, these probes provide a quick, reliable, and secure connection to metal parts. They are perfect for molds, presses, and industrial machines under high stress.

Minimum diameter

5,7mm

Minimum temperature

-50°C

Maximum temperature

+400°C

Minimum order

200€

Delivery time

≈ 5 week

Price

On request

Sensors available

All

Maximum waterproofing

IP67

Where are bayonet probes used ?

Surface temperature monitoring

Perfect for measuring metal surfaces without immersion, offering good thermal responsiveness and direct contact.

Quick Assembly and Disassembly

The locking mechanism allows for easy probe changes without tools, facilitating regular maintenance.

Fastening in Vibrating Environments

The bayonet system ensures stable retention even under strong vibrations, preventing any detachment or misalignment.

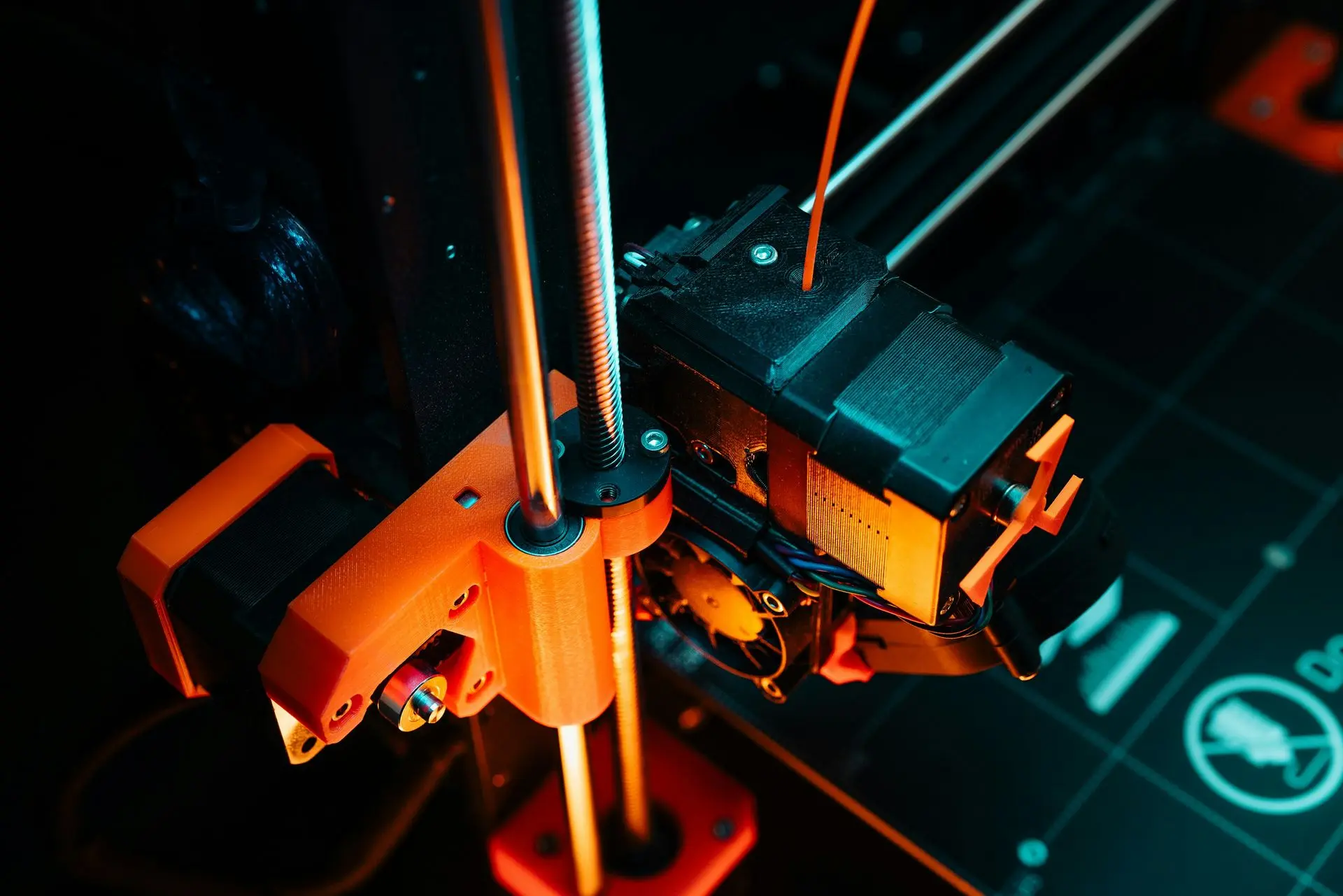

Plastic production

Frequently used in extruders, molding, or polymer processing machines, where precision and speed are crucial.

On molds and presses

Ideal for monitoring temperature in contact with heated metal parts in injection molds or hot presses.

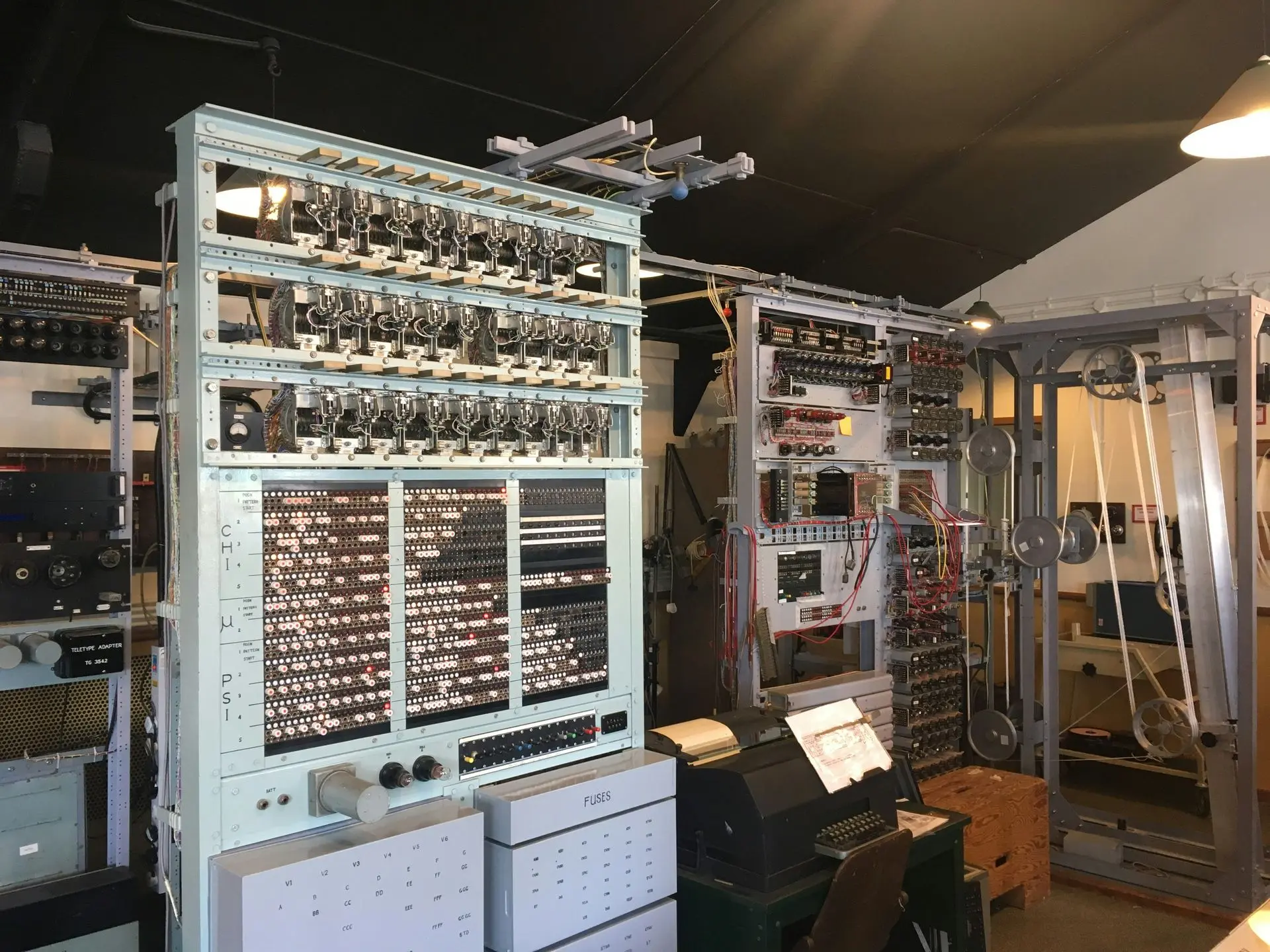

Industrial machine tools

Installed on mechanical areas requiring robust fastening and reliable contact to monitor thermal changes.

Get an offer

Why choose a bayonet temperature probe ?

Bayonet probes are designed for environments where speed, precision, and secure placement are essential. With their secure fastening system, they integrate perfectly into industrial machines under mechanical stress.

1. Constant pressure fastening

The internal spring ensures continuous and even pressure, providing stable measurement even with thermal or mechanical variations.

2. Standardized mounting

The bayonet system is compatible with many industrial supports, limiting adaptations and reducing integration costs.

3. Express replacement

Its design allows for ultra-fast probe changes, perfect for minimizing machine downtime during maintenance.

4. No unintentional loosening

The mechanical lock eliminates any risk of contact loss due to vibrations or frequent handling.

5. Targeted measurement

Ideal for precise measurement points where the probe must remain perfectly positioned without the risk of slipping.

6. Consistent reliability over time

Its robust design allows for repeated installation/removal cycles without performance degradation.