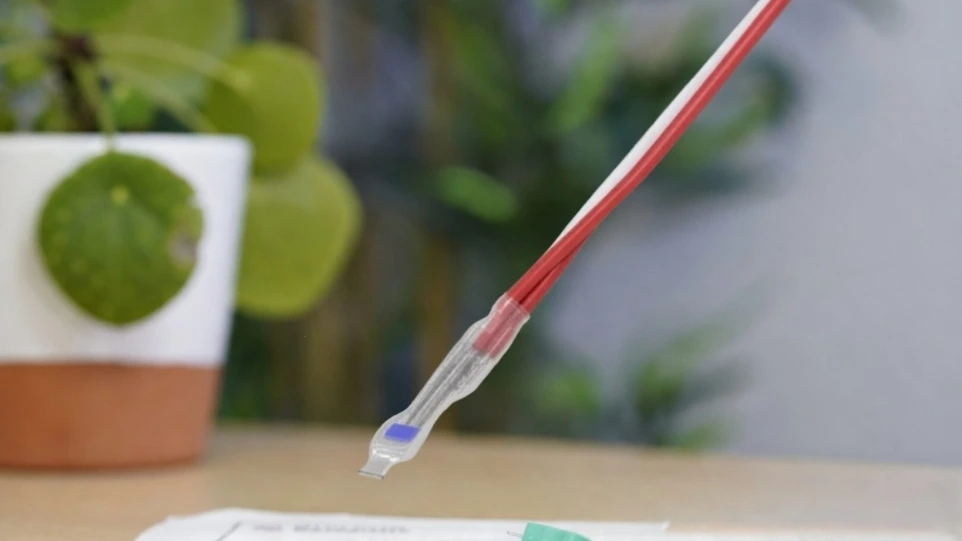

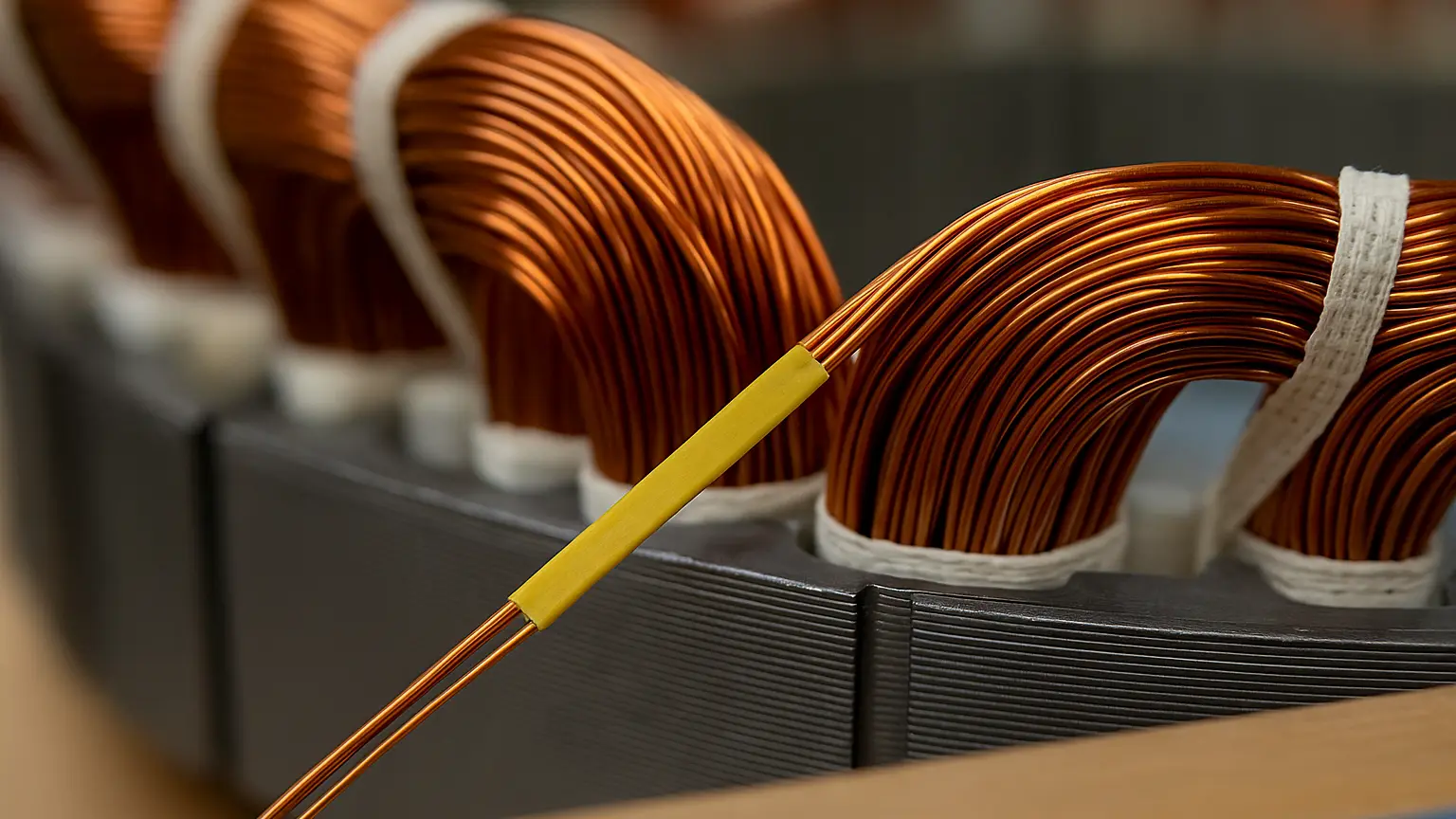

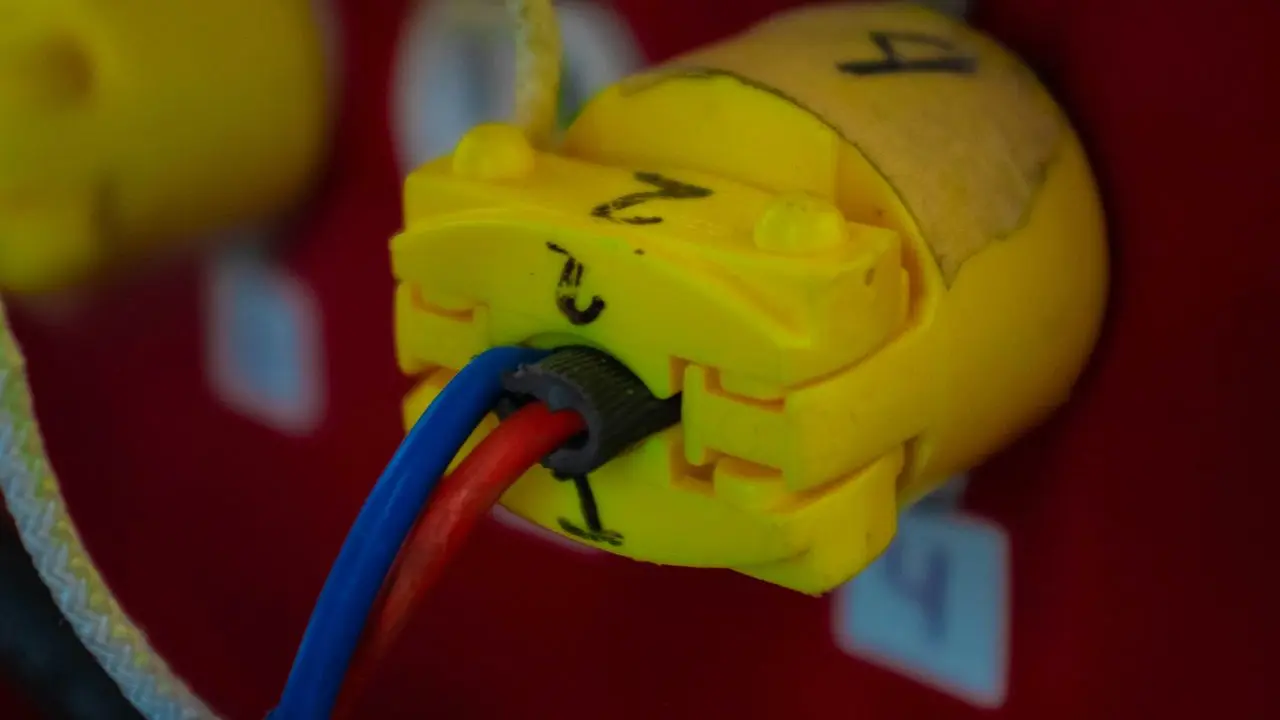

Winding temperature probes

Specially designed for electrical windings.

These ultra-thin probes are suitable for thermal monitoring of motors, transformers, or generators, being directly integrated into the windings. They offer reliable precision in compact and electrically sensitive environments.

Minimum diameter

2,7mm

Minimum temperature

-60°C

Maximum temperature

+200°C

Minimum order

200€

Delivery time

≈ 5 week

Price

On request

Sensors available

All

Maximum waterproofing

IP67

Where are bayonet probes used ?

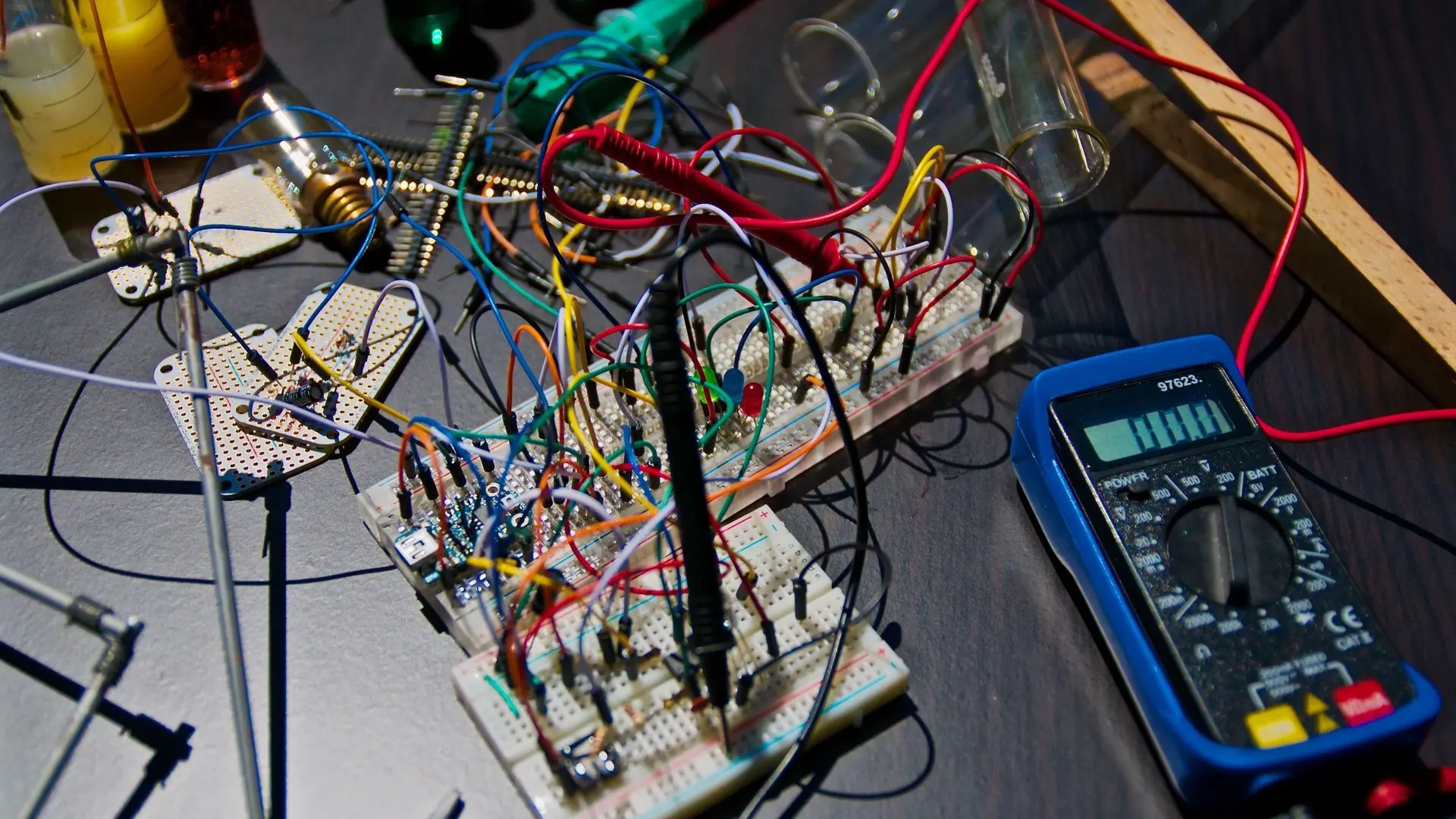

Continuous thermal monitoring

Perfect for continuous measurement in isolated or hard-to-reach environments once the equipment is assembled.

Compact industrial equipment

Installed where space is very limited, without compromising measurement accuracy.

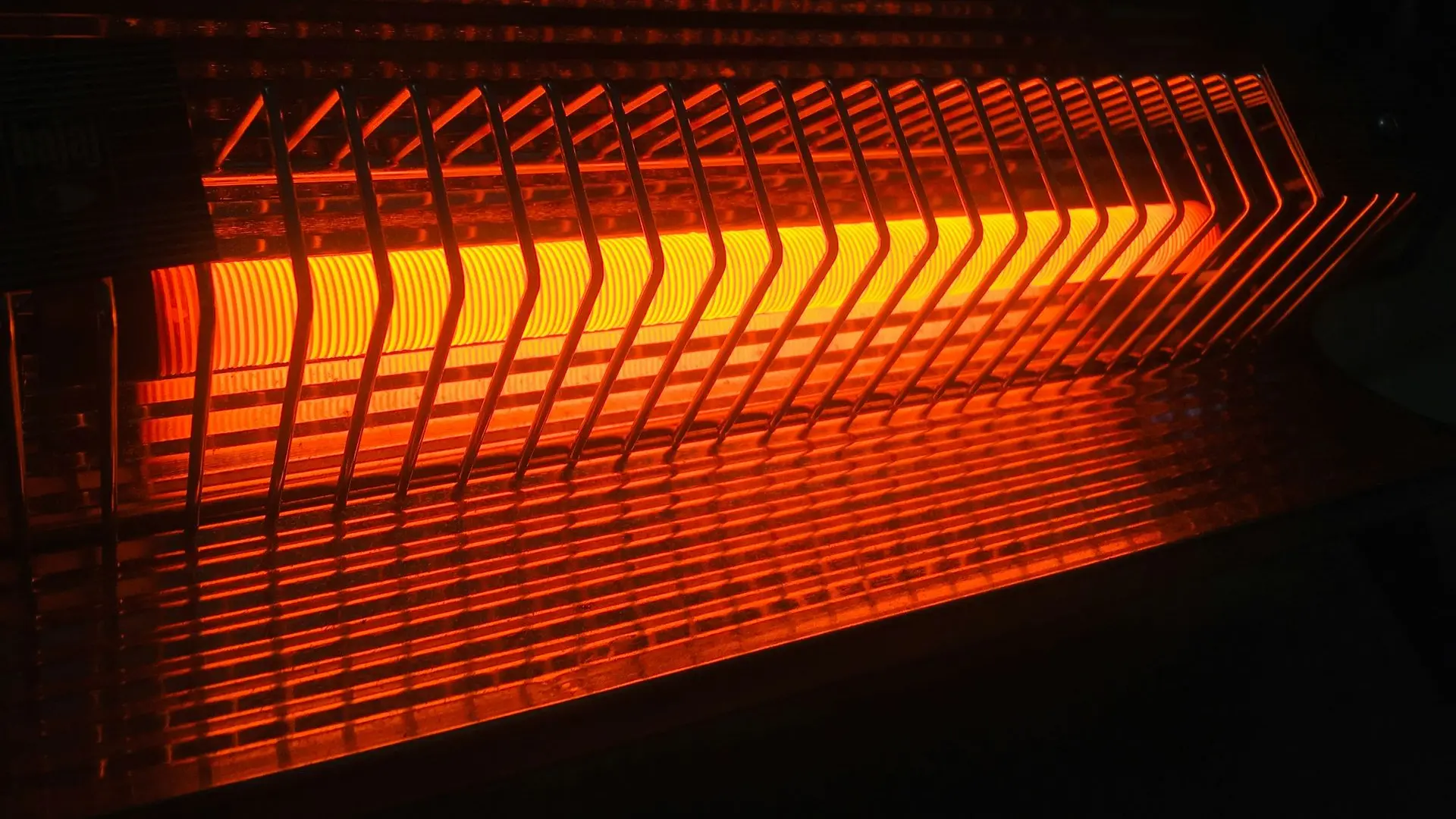

Brake or clutch coils

Used to monitor local thermal rises in electromagnetic systems.

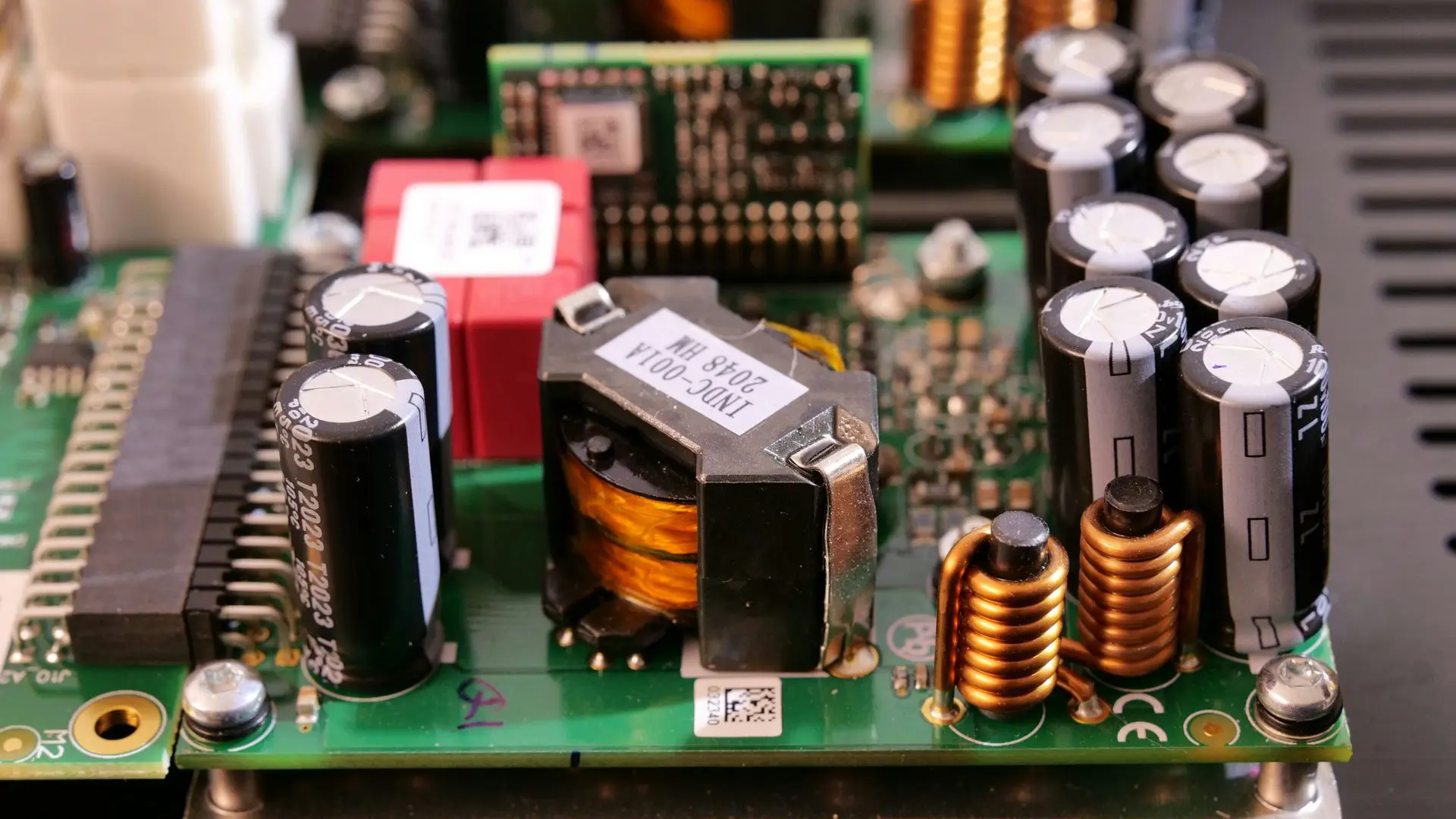

Alternators and generators

Ensure precise measurement at the core of coils, even in vibrating or confined environments.

Electric motors

Directly integrated into stator windings to prevent overheating and optimize motor lifespan.

Transformers

Monitor the internal temperature of windings to prevent damage from overheating.

Get an offer

Why choose a winding temperature probe ?

Choosing a winding probe means opting for integrated, reliable, and durable measurement directly at the heart of electrical components. Ideal for compact and sensitive environments, it ensures precise thermal monitoring without compromising on space or safety.

1. Ultra-thin design

Designed to fit between coils without disrupting the winding or altering the internal structure.

2. Close to the source measurement

Placed at the very heart of the winding, it allows precise detection of the conductor's actual temperature.

3. Enhanced thermal safety

It allows for anticipation of overheating, thus protecting expensive equipment from overloads.

4. Electromagnetic compatibility

It's design minimizes electromagnetic interference, ensuring reliable measurement in intense electrical environments.

5. Invisible integration

Integrated during manufacturing or repair, it remains completely hidden and protected, without hindering assembly.

6. Long-term reliability

Designed to operate continuously without drift, even under repeated thermal stress.