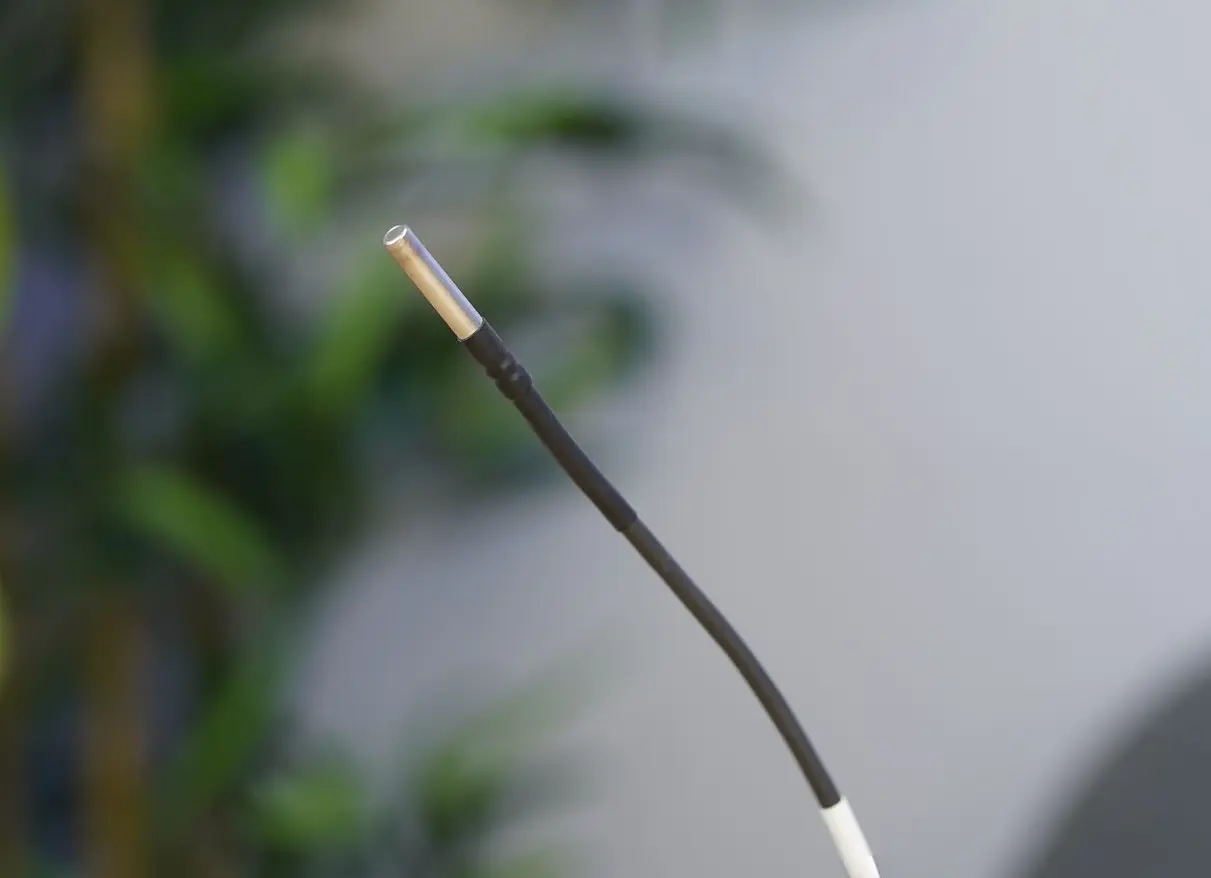

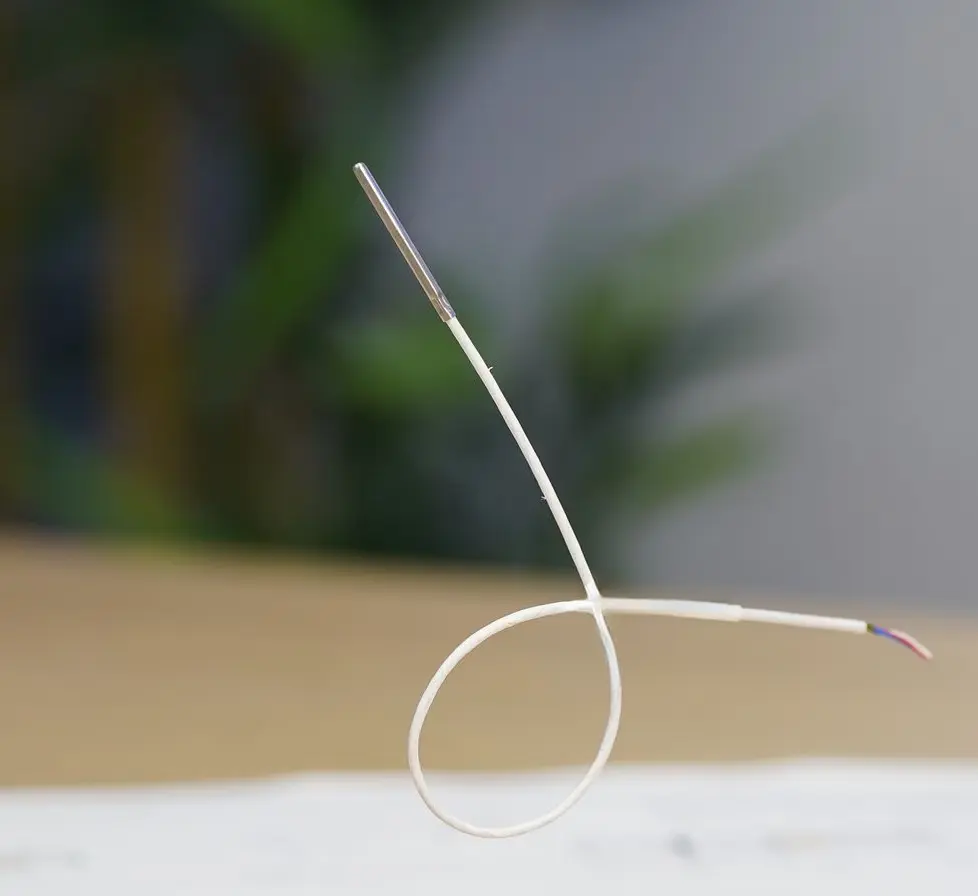

Smooth tube temperature probes

Simple, economical, and versatile measurement.

Smooth tube probes integrate easily into your equipment and processes without complex mounting.

Minimum diameter

1,5mm

Minimum temperature

-190°C

Maximum temperature

+400°C

Minimum order

200€

Delivery time

≈ 5 week

Price

On request

Sensors available

All

Maximum waterproofing

IP67

Where are smooth tube probes used ?

Laboratories and technical environments

Perfect for confined spaces or sensitive installations. They offer stable and precise measurement without disrupting the process.

Process automation

Easy to integrate into automated systems, they ensure precise and continuous thermal monitoring. Ideal for adjusting production parameters and ensuring product quality.

Food industry

Their smooth surface facilitates cleaning and limits contamination risks. They are used in production areas or cold rooms to control air or fluids.

Industrial machines and equipment

Used to monitor the temperature of engines, metal structures, or technical parts. Their robust design allows for surface mounting or partial insertion.

Heating, ventilation, and air conditioning

Smooth tube sensors are ideal for measuring air temperature in ducts, shafts, or rooms. Their compact design allows for quick installation without disrupting airflow.

Pipes and non-pressurized tanks

They are inserted directly into pipes or non-pressurized containers. Perfect for quick measurement of liquids or gases, without mechanical constraints. A simple and economical solution.

Get an offer

Why choose a smooth tube temperature probe?

Choosing a smooth tube probe means opting for a versatile, reliable, hygienic, and easy-to-integrate sensor while controlling costs. It's the ideal solution for precise measurements in diverse environments, from the cleanest to the most demanding.

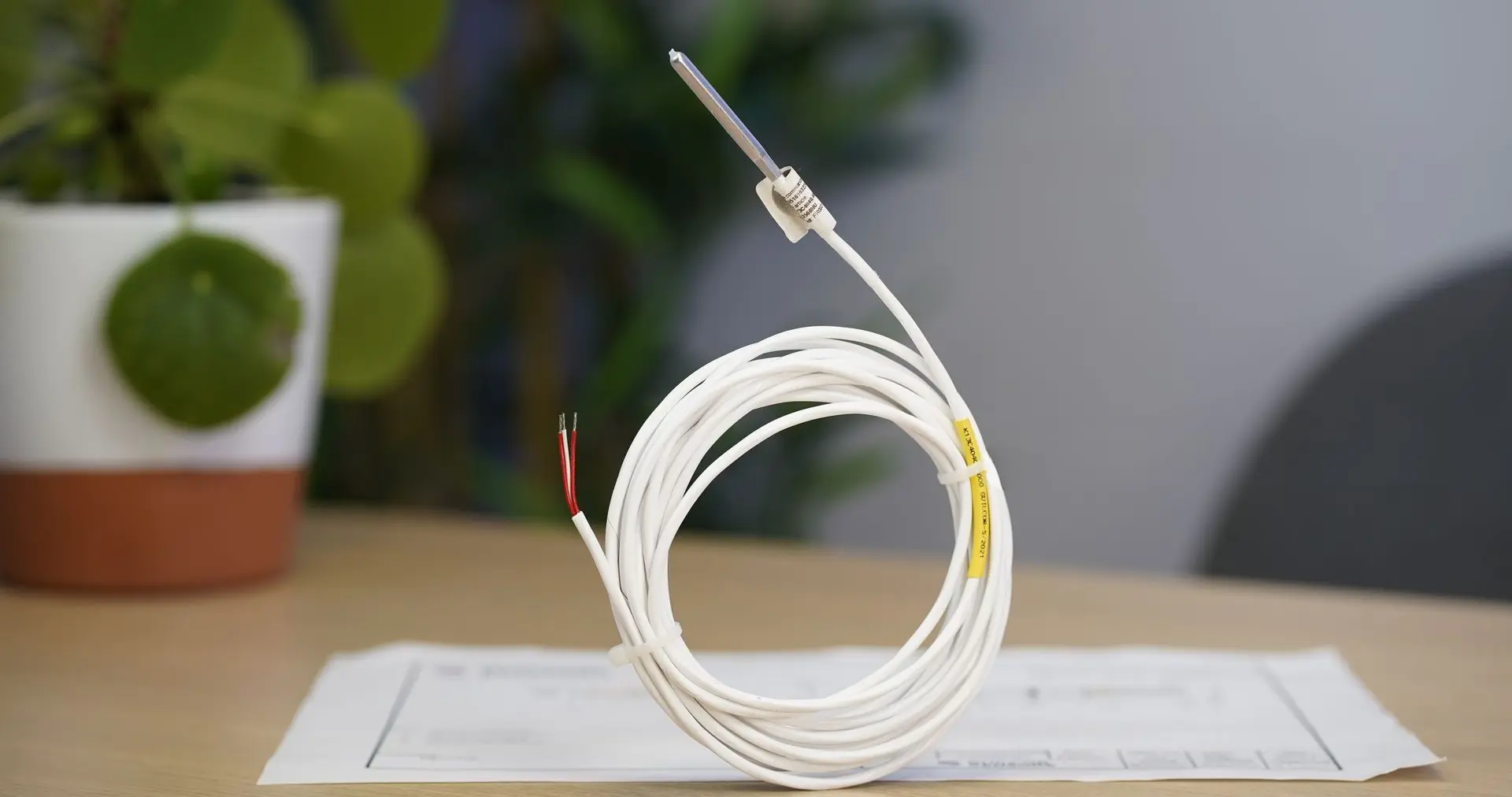

1. Ease of integration

Thanks to their simple and smooth shape, these probes are quickly installed in a wide variety of environments, whether in ducts or tanks. No complex mounting is needed: their implementation is quick and hassle-free.

2. Easy cleaning

Their smooth, seamless surface allows for easy cleaning, a crucial advantage in sectors where hygiene is paramount, such as food, medical, or laboratory settings. Fewer crevices mean less risk of contamination.

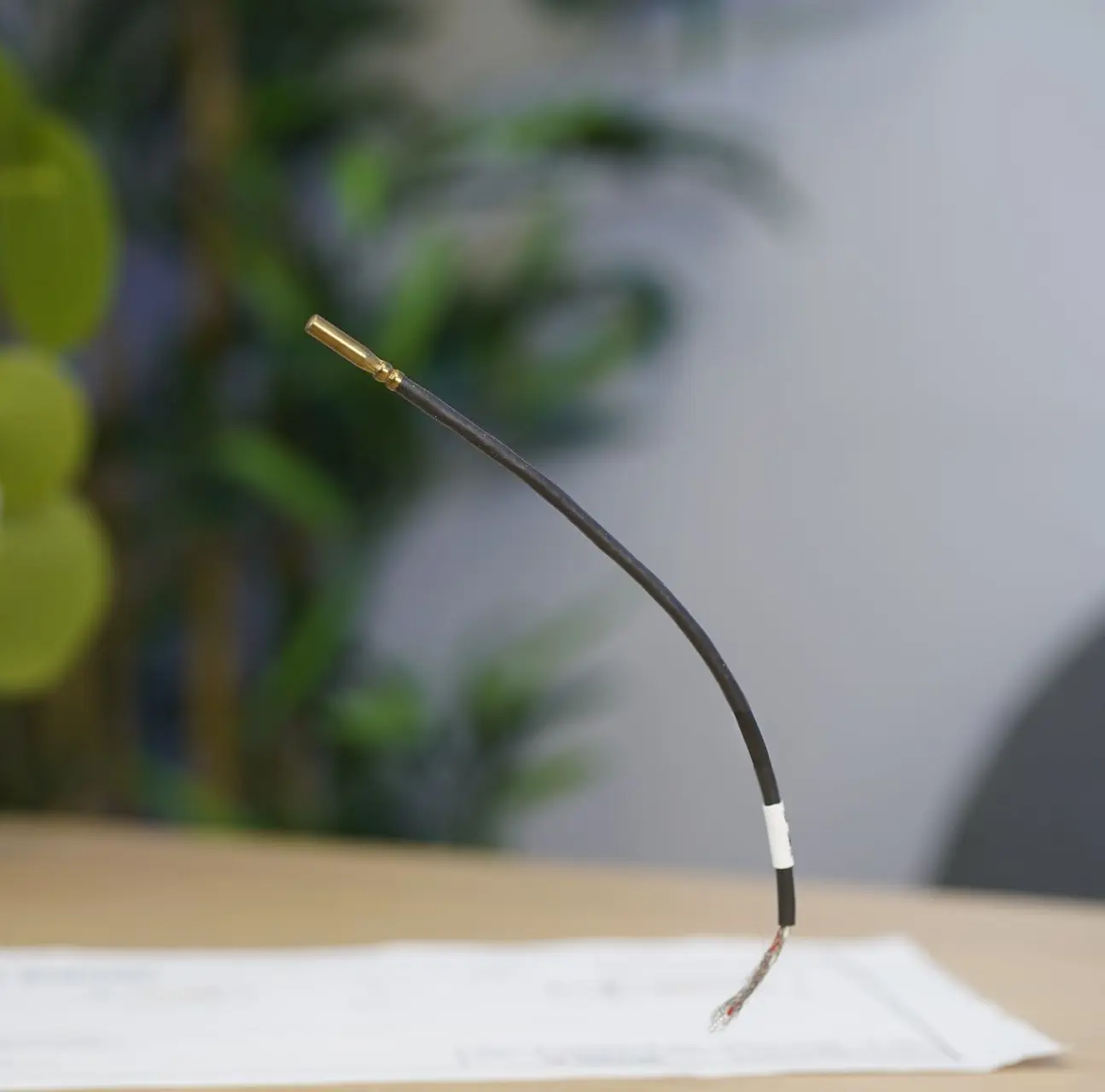

3. Excellent thermal conductivity

Their design promotes excellent heat transfer between the measured medium and the internal sensor. The result: precise, responsive, and reliable readings, even in environments with frequent temperature variations.

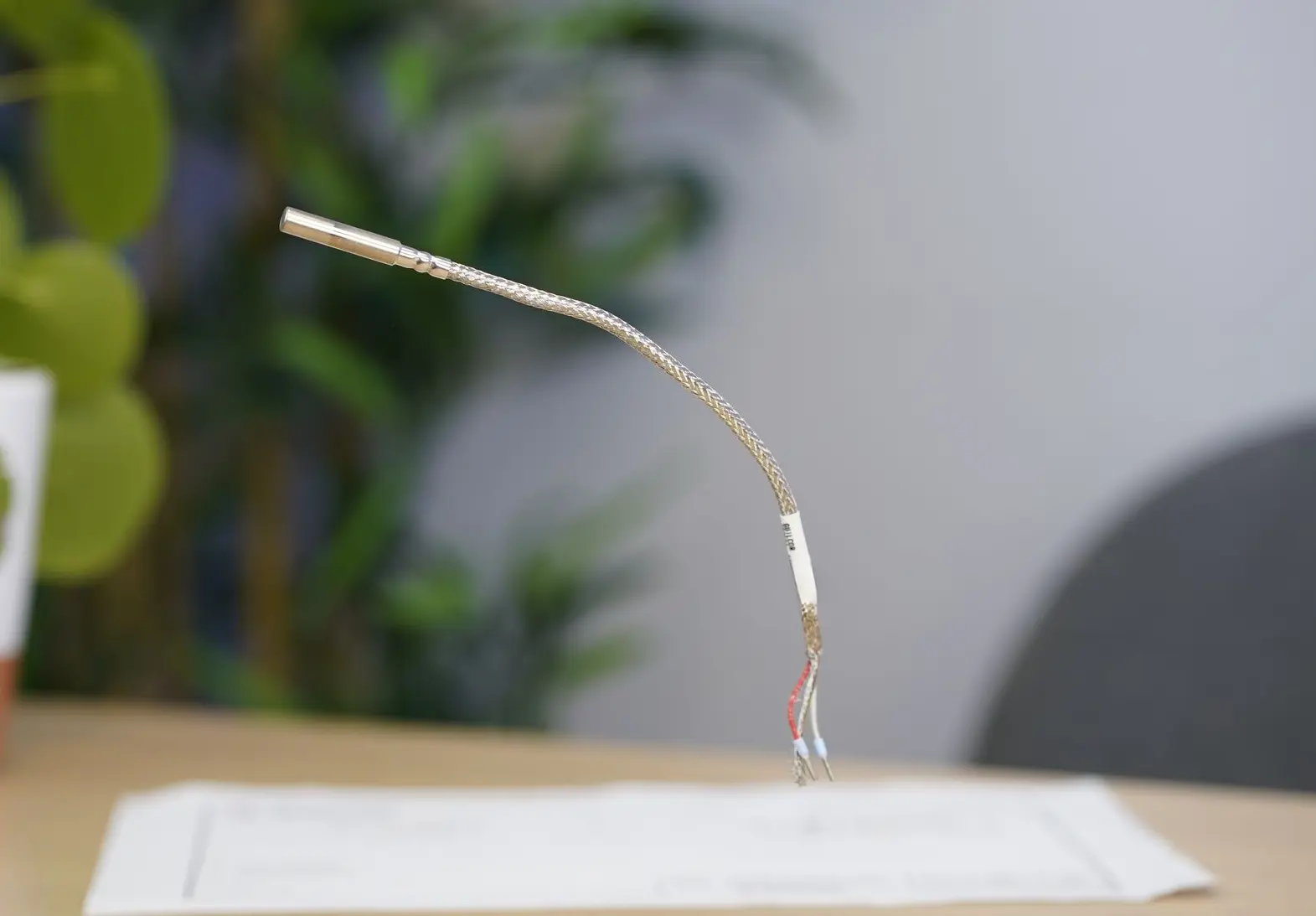

4. Robustness and durability

The smooth tube, often made of stainless steel or resistant alloys, withstands shocks, vibrations, and demanding industrial conditions. A reliable choice for durable installations.

5. Versatility of applications

From heavy industry to HVAC and automated processes, these probes fit everywhere. Their simplicity makes them a standard adaptable to many use cases without major modifications.

6. Optimized cost

No sophisticated fittings, no special machining: their streamlined design offers an efficient technical solution at a controlled price. Ideal for projects requiring multiple measurement points.