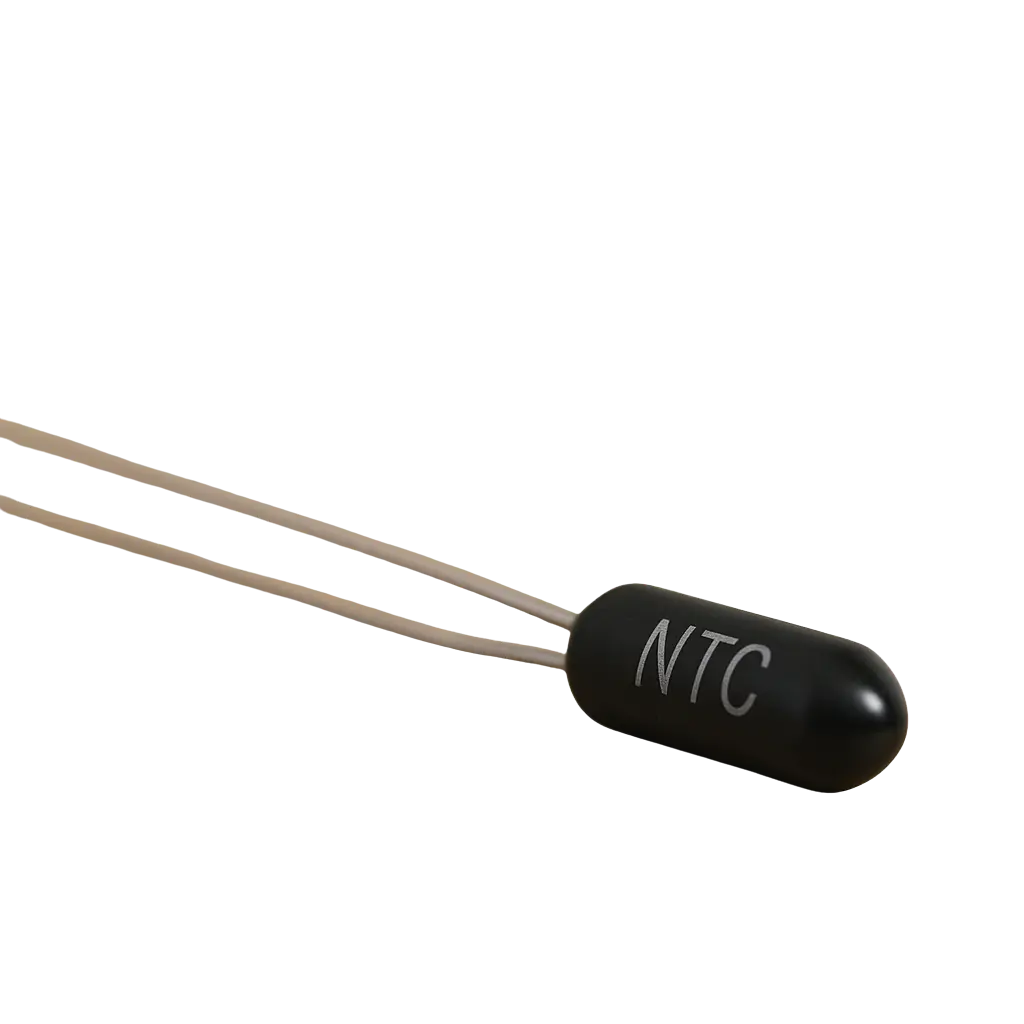

NTC temperature sensors

Precise and sensitive thermistor sensors, ideal for rapid detection of temperature variations.

What is an NTC sensor ?

An NTC sensor (Negative Temperature Coefficient) is a temperature sensor whose resistance decreases as the temperature increases. It belongs to the family of thermistors, which are temperature-sensitive components.

Essentially, the hotter the environment gets, the lower the sensor's resistance becomes, allowing for precise measurement of temperature variations. This behavior is ideal for applications requiring rapid and reliable detection of thermal changes.

We integrate any sensor into any probe

✽ What NTCs Offer

Discover the main four benefits

Quick response to temperature variations

NTC sensors offer a very short response time due to their low thermal mass. This makes them particularly effective for applications requiring near-instantaneous detection of changes, such as medical devices or thermal safety systems.

Excellent value for money

Compared to RTDs or thermocouples, NTC sensors are more economical while ensuring good performance. A strategic choice for projects requiring large quantities or reduced unit costs.

High accuracy within common temperature ranges

Their non-linear response curve is very precise over temperature ranges from -40 °C to +125 °C. This is an advantage for control systems where reliable measurement is essential without resorting to more expensive sensors.

Easy integration into all environments

Thanks to their compact format, NTC sensors easily integrate into printed circuits, sealed enclosures, or mobile applications. They are available in various forms: beads, probes, plastic housings, etc.

Do you have a project ? Let's talk about it.

Whether for a prototype, mass production, or a specific application, we design custom probes using NTC sensors

tailored to your technical and environmental constraints.

Frequently asked questions

Here are some common questions about our NTCs.

A thermistor NTC (Negative Temperature Coefficient), or CTN in French, is a resistive sensor primarily used for temperature measurement or as an inrush current limiter.

It has a thermal sensitivity about 5 times higher than silicon sensors (silistors) and up to 10 times higher than platinum RTD sensors.

Used in ranges from -55 °C to +200 °C, the NTC thermistor is made of ceramic or polymer materials, unlike RTDs which are metallic.

The materials used directly influence its thermal response, stability, and performance.

The resistance of an NTC sensor decreases non-linearly with increasing temperature.

Its sensitivity is expressed as a percentage change per °C, typically between -3% and -6%/°C depending on the materials.

Standard versions are accurate between -55 °C and +200 °C, but some specific probes can operate near absolute zero or beyond 150 °C.

Their steep rate of change makes them more sensitive than RTDs over a narrow range, although RTDs offer higher accuracy and a wider range (up to 800 °C).

Compared to RTDs, NTC thermistors :

- are smaller,

- offer faster response,

- are less sensitive to shock,

- are cheaper, but they are slightly less accurate and limited to narrower temperature ranges.

Compared to thermocouples, NTCs offer better accuracy at low temperatures, require less conditioning circuitry, but cannot handle extreme temperatures (thermocouples can exceed 1000 °C).

In summary, NTC thermistors are ideal for applications where precision, sensitivity, and cost are priorities, especially at low temperatures.

The choice of mathematical model depends on the targeted temperature range and required accuracy :

-

Linear approximation : valid only over a very narrow range.

-

Beta equation : correct accuracy (~±1 °C) between 0 °C and +100 °C.

-

Steinhart-Hart equation : the most accurate (~±0.15 °C), suitable for demanding applications.

If these equations are insufficient, point-by-point calibration with a lookup table can be used.

The standard symbol for an NTC thermistor according to the IEC standard is shown below.

Self-heating is a phenomenon that occurs when a current passes through the NTC thermistor. Like any resistive component, the thermistor dissipates energy as heat, which can lead to a local temperature rise and skew the measurement if not controlled.

The intensity of this heating depends on several factors :

- the current flowing through the thermistor,

- the surrounding environment (air, liquid, ventilation),

- the physical characteristics of the sensor (dissipation coefficient, surface area, encapsulation).

In some cases, this effect can be deliberately exploited (e.g., liquid detection in a tank), but generally, it should be minimized to ensure accurate measurement.