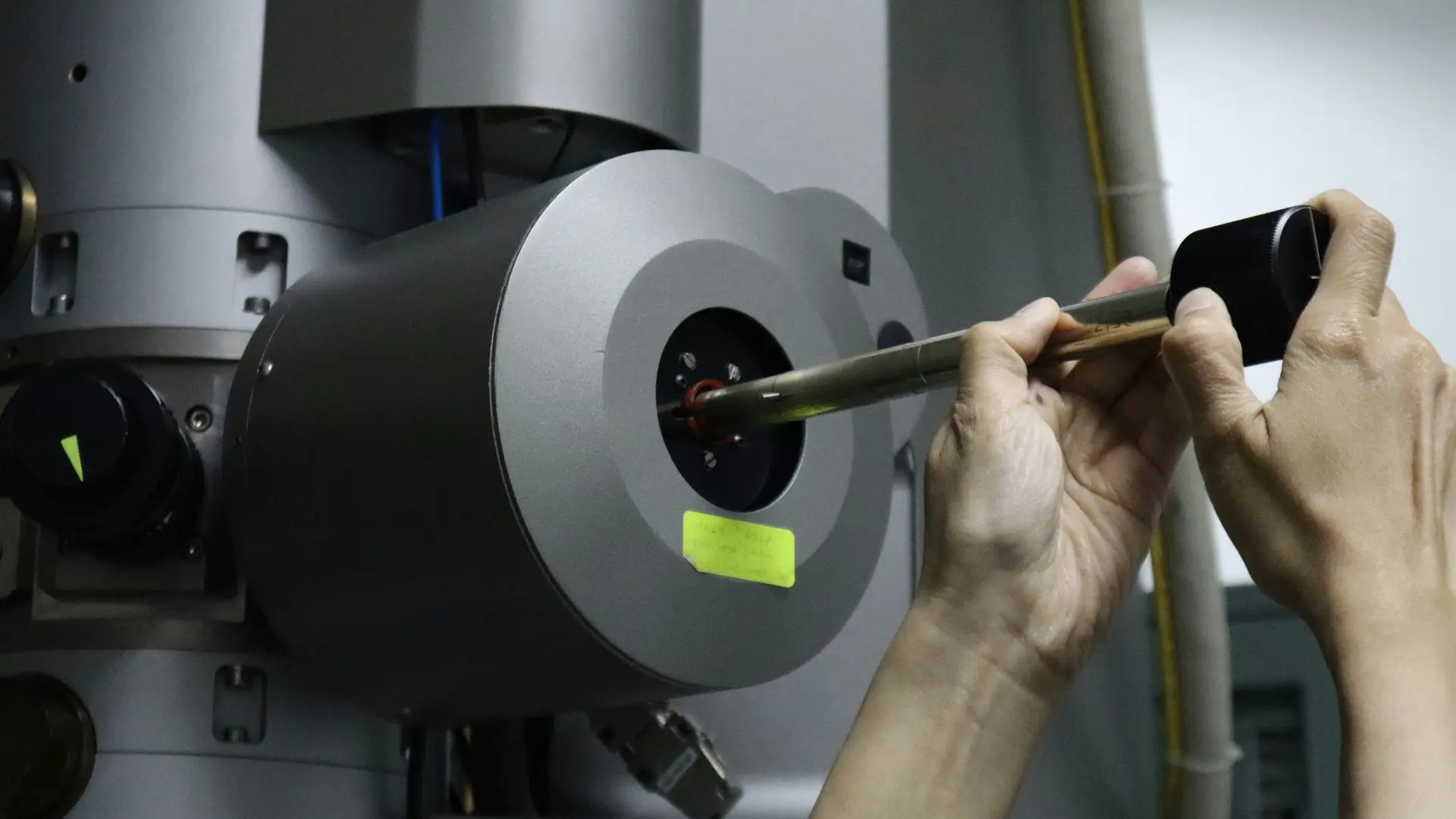

Thread temperature probes

For secure, quick, and uncompromising installation.

Equipped with mechanical threading, these probes allow reliable and waterproof installation in pipes, tanks, or industrial equipment. The integrated fitting ensures stable mounting without play or leaks.

Minimum diameter

4mm

Minimum temperature

-190°C

Maximum temperature

+400°C

Minimum order

200€

Delivery time

≈ 5 week

Price

On request

Sensors available

All

Maximum waterproofing

IP67

Where are probes with fittings used ?

Sanitary or HVAC installations

Perfect for hot water networks, heating circuits, or chilled water production units, with reliable installation.

Industrial fluid monitoring

Used to measure liquids (water, oil, glycol…) in technical or cooling processes.

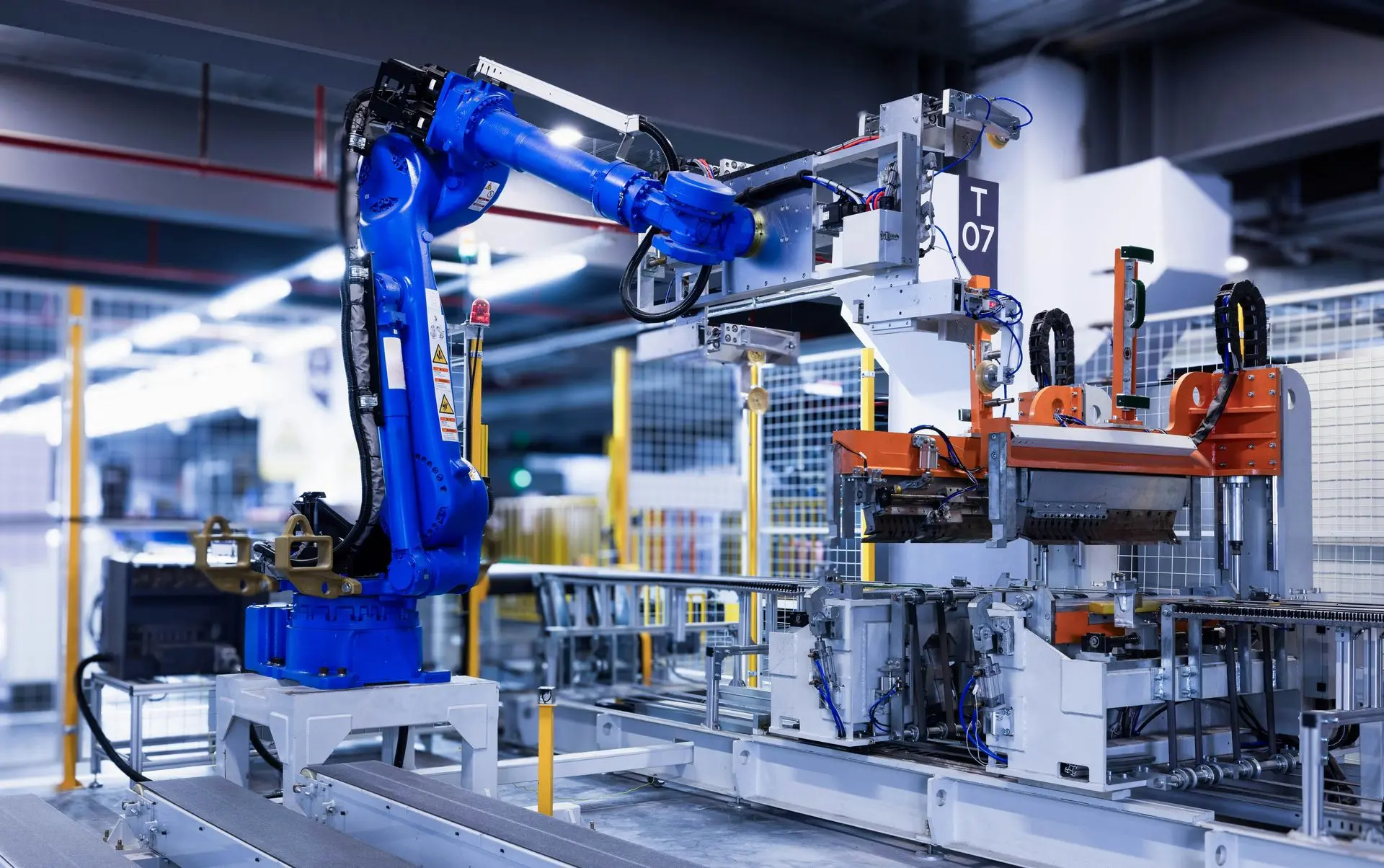

Automated production lines

Probes with fittings are easily installed on automated machines to ensure continuous thermal monitoring.

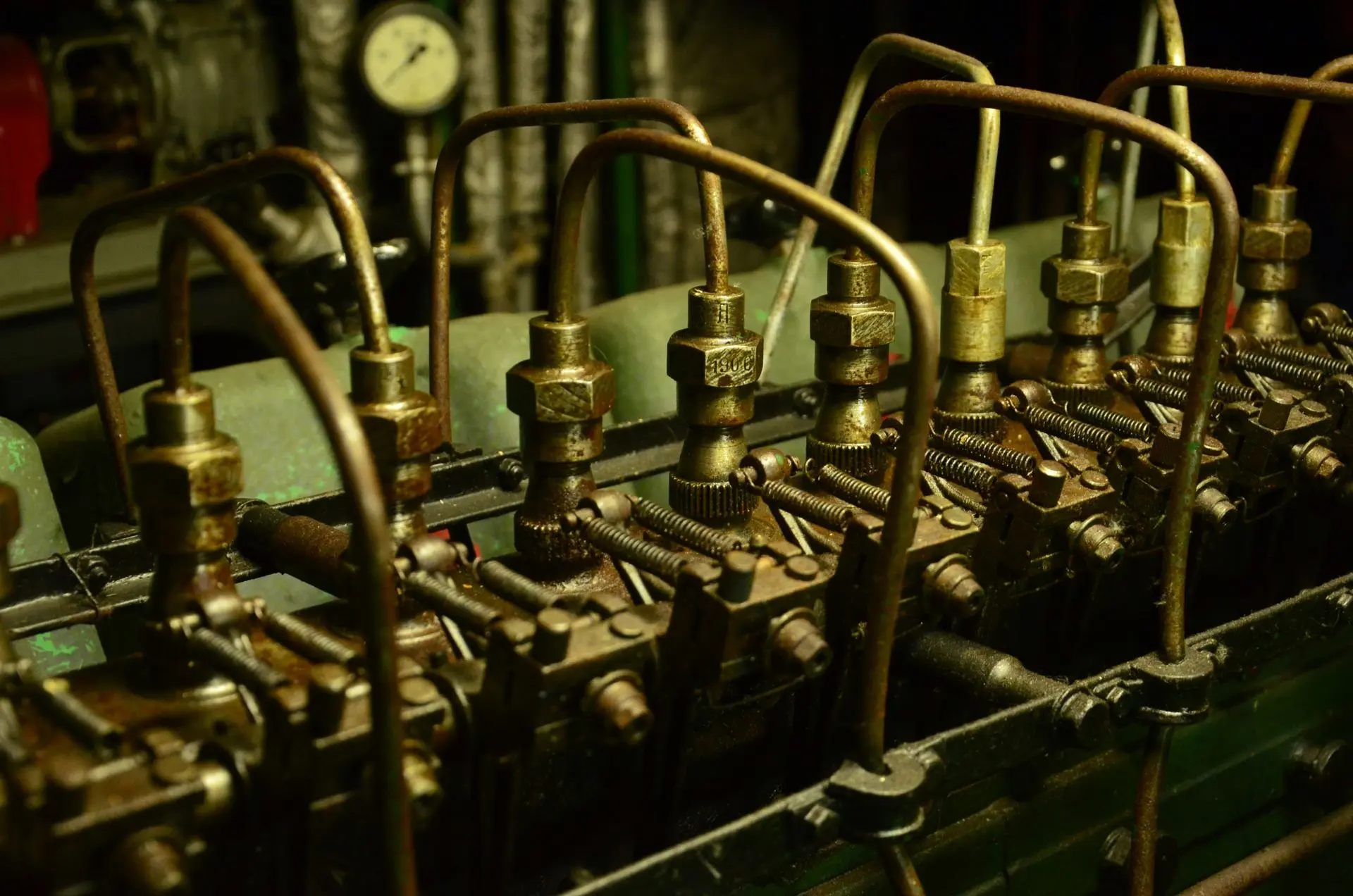

Thermal or hydraulic equipment

Direct integration into boilers, heat exchangers, or thermal fluid systems.

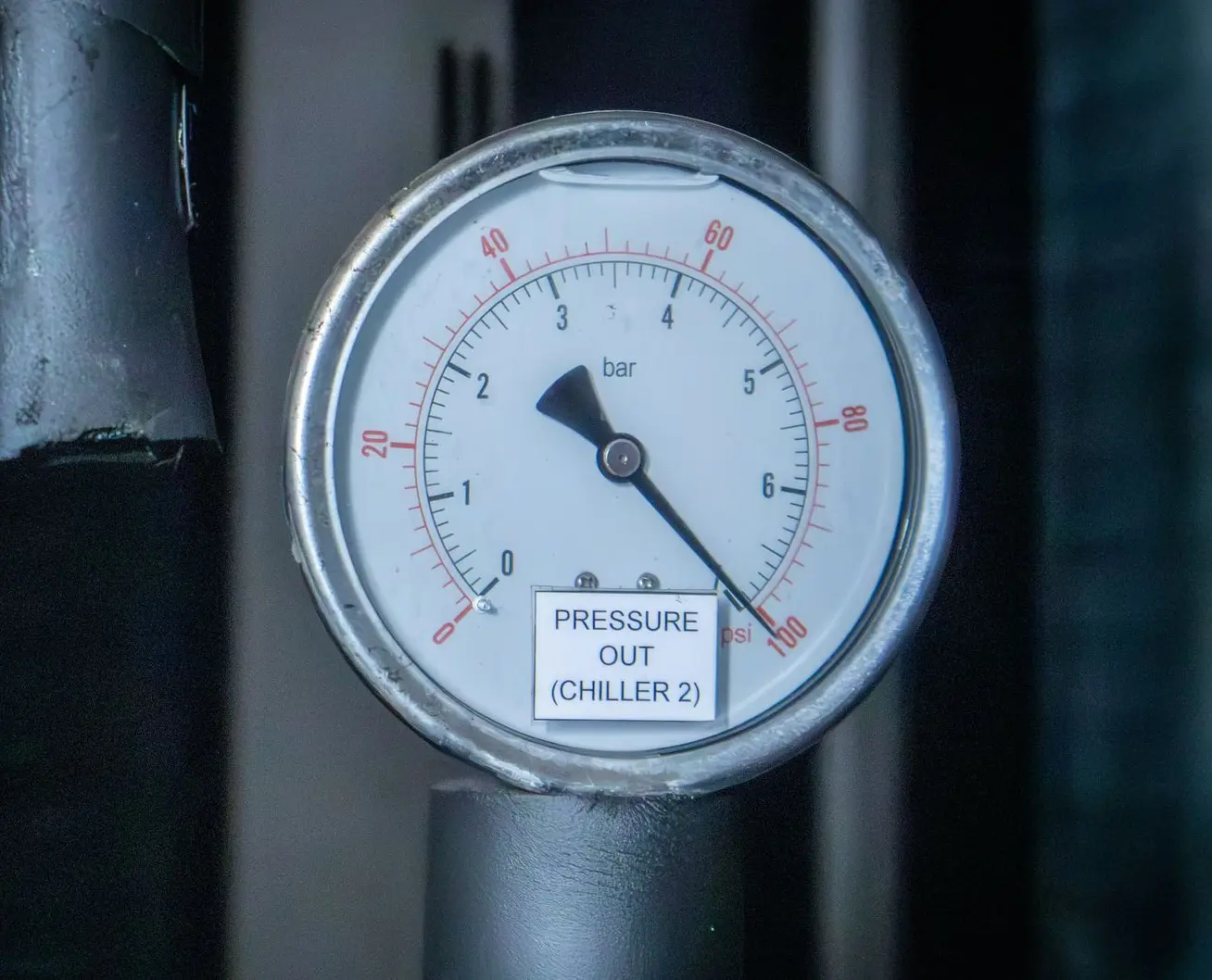

Pressurized piping

The threaded fitting allows secure mounting in pressurized circuits without risk of leakage.

Industrial tanks and reservoirs

For reliable measurement inside metal containers, even when subject to agitation or temperature variations.

Get an offer

Why choose a temperature probe with a fitting ?

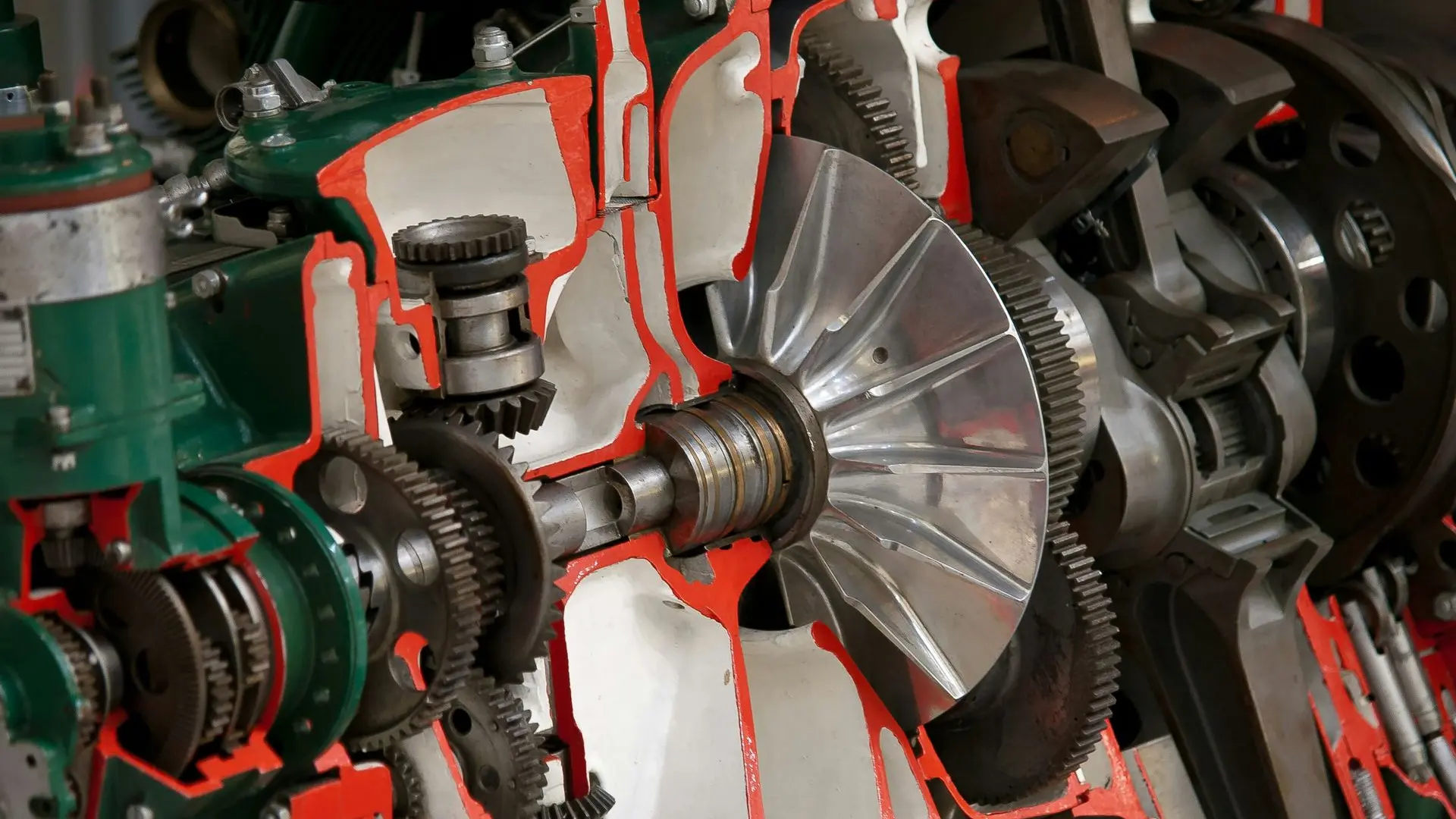

Choosing a probe with a fitting means opting for a reliable, secure sensor that is easy to integrate into any pressurized or mechanical system. The threaded fitting ensures a robust attachment and long-lasting seal, even in the most demanding industrial environments.

1. Secure and leak-free attachment

The mechanical fitting enables a watertight installation in pressurized circuits or in the presence of fluids. It prevents play, leaks and ensures a solid, durable connection.

2. Simple and quick installation

Thanks to its standardized threading, the probe screws directly onto the installation without additional accessories. This reduces installation time and the risk of errors.

3. Easy maintenance

Removal is simple and quick, facilitating inspection, calibration, or replacement operations. There is no need to dismantle the entire system.

4. Precise measurement in the process

The fitting allows optimal immersion of the sensitive element in the fluid. This ensures rapid thermal response and measurement close to the critical point.

5. Standardization of connections

Available in various industrial thread sizes (M10, G1/2, etc.), this probe easily integrates into existing installations, avoiding costly adaptations.

6. Suitable for demanding environments

Designed to withstand vibrations, high temperatures, and mechanical stresses, it is ideal for factories, thermal networks, or automated systems.