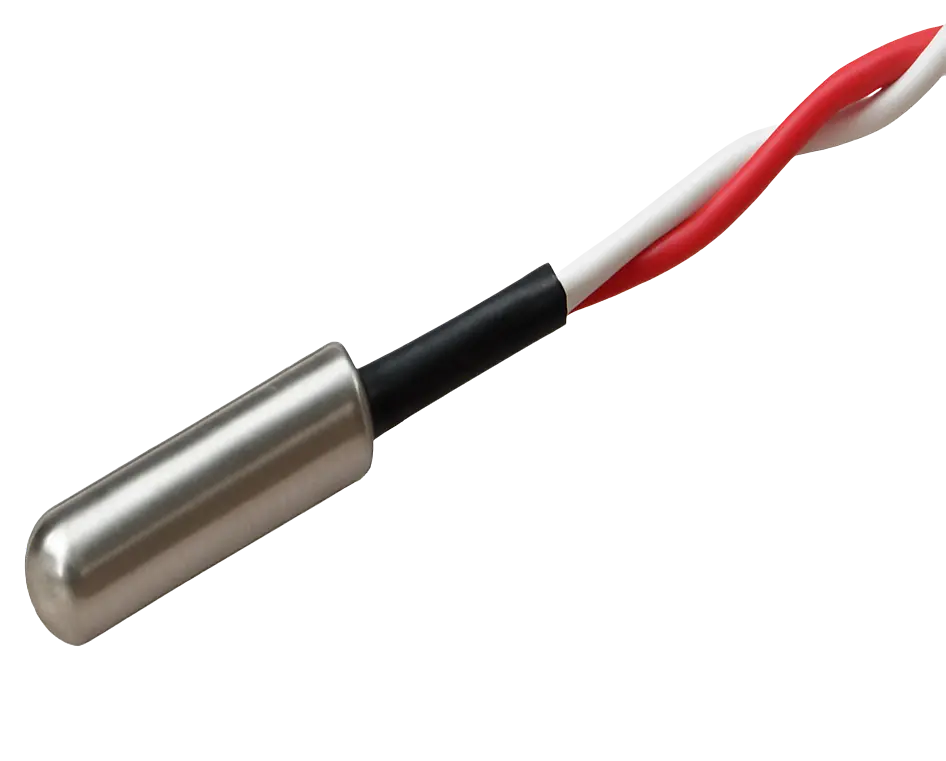

Thermocouples temperature sensors

Robust and versatile sensors capable of measuring extreme temperatures in the most demanding industrial environments.

What is a thermocouple sensor ?

A thermocouple is a temperature sensor based on the Seebeck effect: it produces an electrical voltage when there is a temperature difference between two junctions of different metals.

This voltage, expressed in millivolts, is proportional to the measured temperature and provides a quick and reliable reading.

Each type of thermocouple (K, J, T, S, etc.) uses a specific combination of metal alloys, which determines its :

- temperature range,

- resistance to harsh environments,

- stability over time.

We integrate any sensor into any probe

✽ What Thermocouple Offer

Discover the main four benefits

Measurement of extreme temperatures

Thermocouples can measure temperatures up to 2500°C, depending on the type used. They are essential in environments where NTC, PTC, or RTD sensors cannot withstand.

Fast response time

Thanks to their low thermal mass, thermocouples react quickly to temperature changes, making them ideal for dynamic or critical processes.

High mechanical robustness

Their simple design and resistance to vibrations, shocks, and chemicals make them reliable in the harshest industrial conditions.

Universal compatibility

They are easily integrated into most industrial control systems (PLCs, controllers, displays) thanks to standardized signals and a wide range of connectors.

Do you have a project ? Let's talk about it.

Tell us your needs : type of thermocouple, usage environment, temperature range, estimated quantity, and purchase frequency.

We assist you in developing sensors tailored to your industrial constraints.

Frequently asked questions

Here are some common questions about our Thermocouples.

The thermocouple is one of the two main types of temperature sensors most used in the industry.

It operates through the thermoelectric effect : a potential difference (voltage) appears between two different metals when subjected to different temperatures.

Note :

- Thermocouples measure this voltage difference, related to temperature.

- Thermistors (NTC/PTC), on the other hand, work on the principle of resistance variation with temperature.

Thermocouples are robust, responsive, and can measure extreme temperatures, up to 1800°C depending on the type.

A thermocouple consists of two different metal conductors, connected at their ends to form :

- a hot junction (measurement point)

- a cold (or reference) junction.

When there is a temperature difference between these two junctions, an electrical voltage (in millivolts) is generated, measured by a voltmeter or transmitter.

The conversion of this voltage into temperature relies on :

- Seebeck coefficients specific to each metal

- standardized reference tables.

This principle, called the Seebeck effect, allows temperature measurement with good accuracy, without external power supply.

Yes, but with caution.

To ensure a reliable measurement, the extension cable used must be either made of :

- the same material as the thermocouple (extension cable)

- calibrated compatible metals, called compensation cables.

Warning :

Using a standard cable (like copper) would distort the measurement, as it would introduce a new parasitic junction.

Additionally, the cold junction must remain at a stable temperature or be electronically compensated in the measuring device.

The IEC 60584-1 standard defines the main types of thermocouples, identified by a letter. Each type corresponds to a combination of alloys and a specific temperature range.

Standard thermocouples :

Type K (Nickel-Chrome / Nickel-Aluminum)

Most common: -200 to 1200°C, inexpensive, robust, sensitivity ~41 µV/°C.

Type J (Iron / Constantan)

- For reducing environments, -40 to 750°C, sensitive to oxidation.

Type T (Copper / Constantan)

- For cryogenics or laboratory applications, from -185 to 300°C.

Type E (Nickel-Chrome / Constantan)

- Excellent sensitivity at low temperatures, -40 to 800°C.

High-temperature thermocouples :

Type N (Nicrosil / Nisil)

- High stability, >1280°C, good alternative to type K.

Types S and R (Rhodium-Platinum / Platinum)

- Very stable, 1000 to 1600°C, used in precision processes.

Type B (30% Rhodium-Platinum / 6% Rhodium-Platinum)

- Up to 1800°C peak, used in very high-temperature industrial furnaces.

The choice of thermocouple also depends on the environment, sheath type, dimensions, and measurement system.

Guilcor Sensors teams can assist you in defining or designing the custom probe suited to your application.