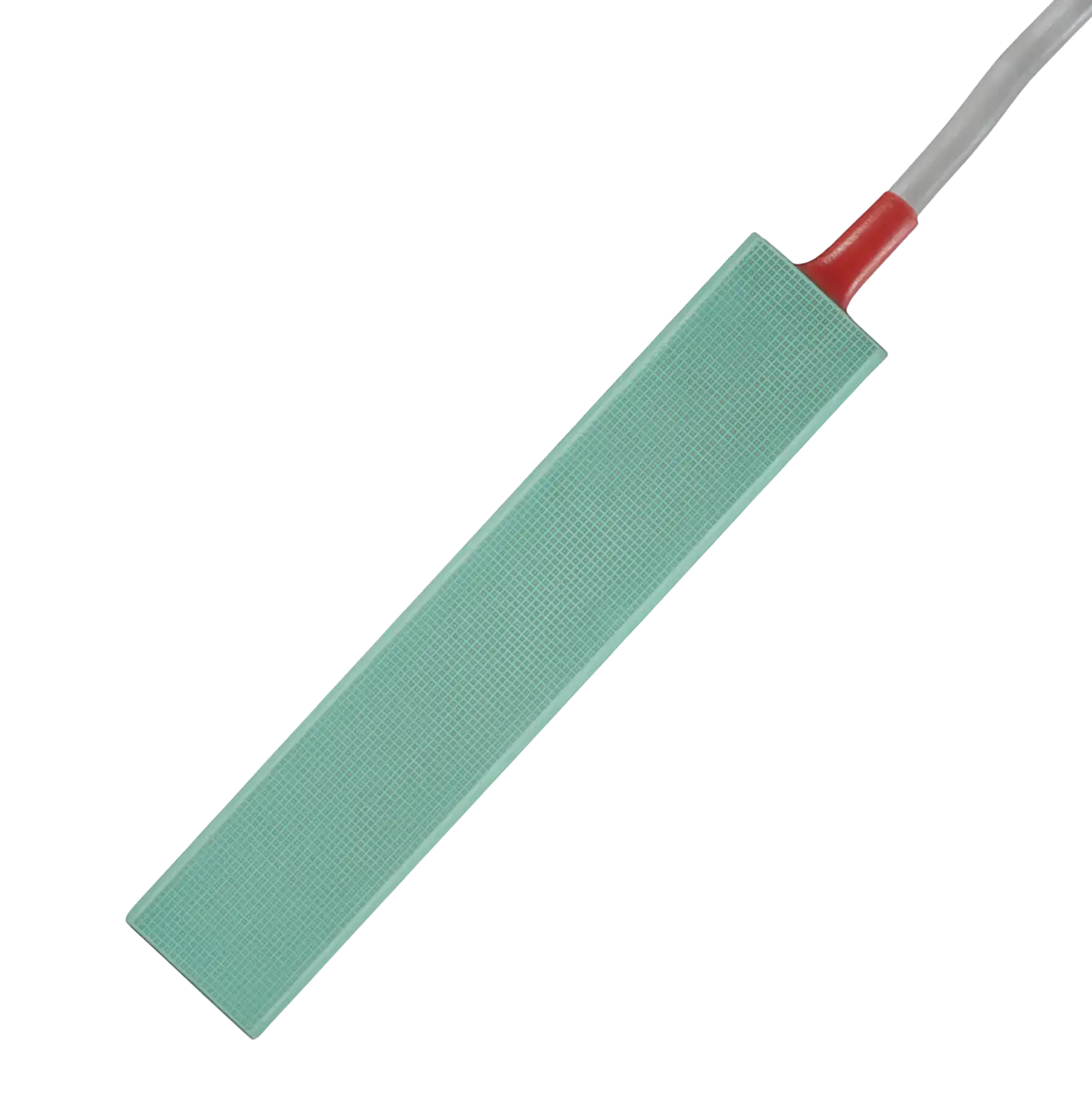

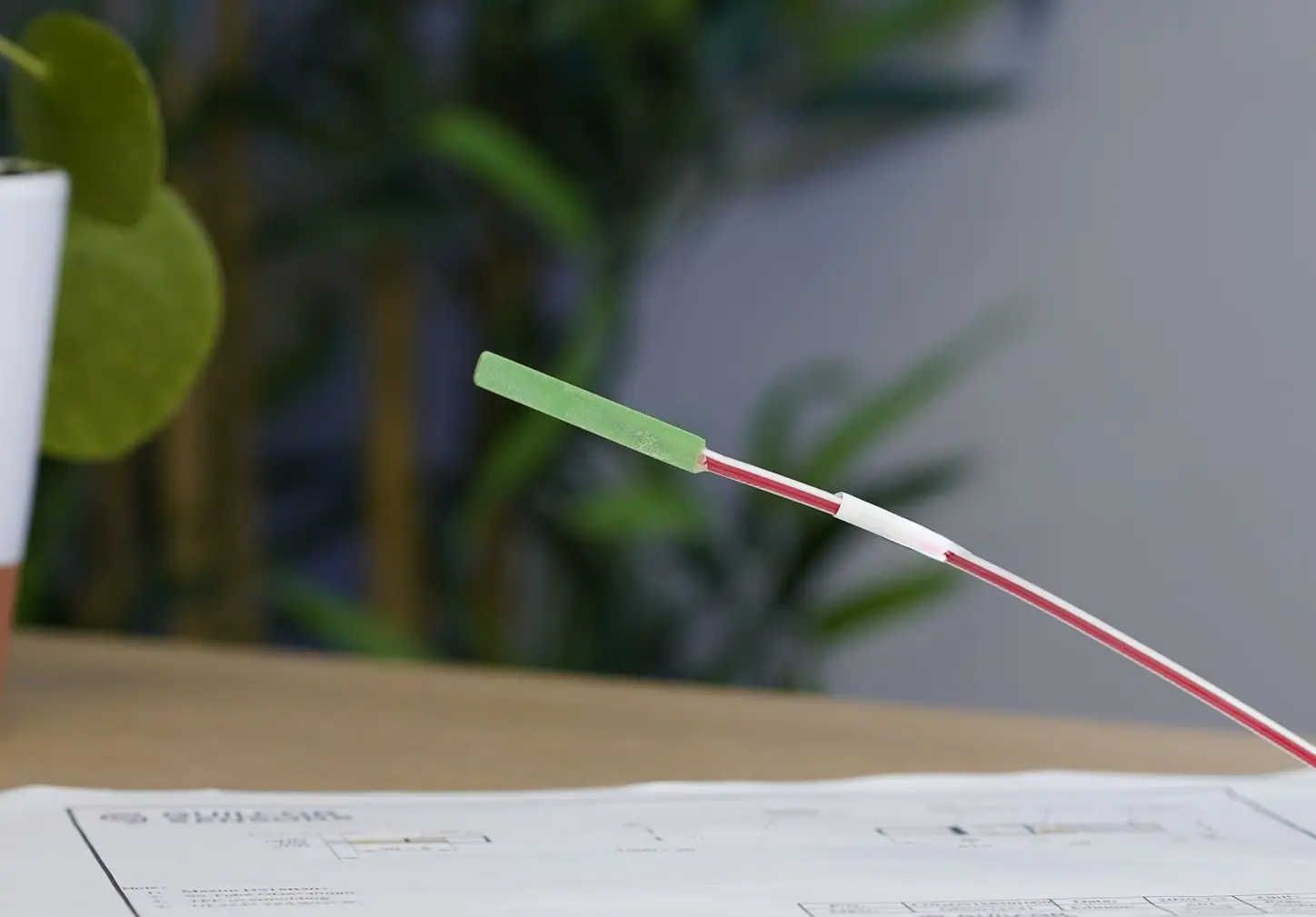

Slot temperature probes

Discreet and precise thermal detection in electric motors.

Notch probes are specially designed to be integrated into the slots of windings, ensuring reliable local measurement without interfering with insulation or assembly. They are used for motor thermal protection and continuous monitoring.

Minimum width

6mm

Minimum temperature

-40°C

Maximum temperature

+250°C

Minimum order

200€

Delivery time

≈ 5 week

Price

On request

Sensors available

All

Maximum waterproofing

IP65

Where are notch probes used ?

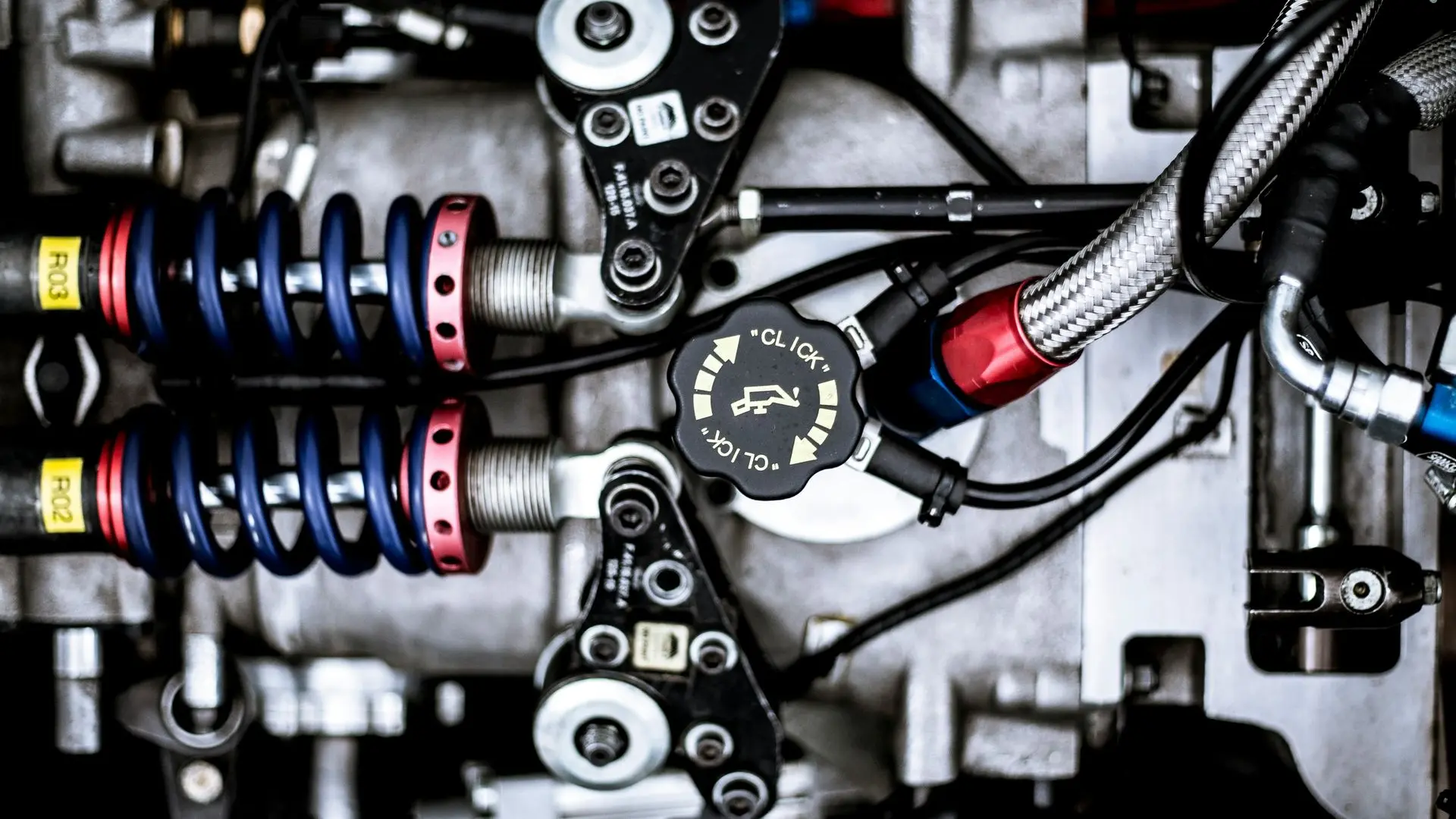

Motor test benches

Used in intensive testing contexts to capture real-time local thermal variations.

Multi-point control

Allows integration of multiple probes in different slots for a detailed thermal profile.

Sensitive rotating machinery

Monitoring of motors subjected to continuous operation or high thermal load.

Motor renovation and maintenance

Perfect for interventions on existing motors without altering the mechanical structure.

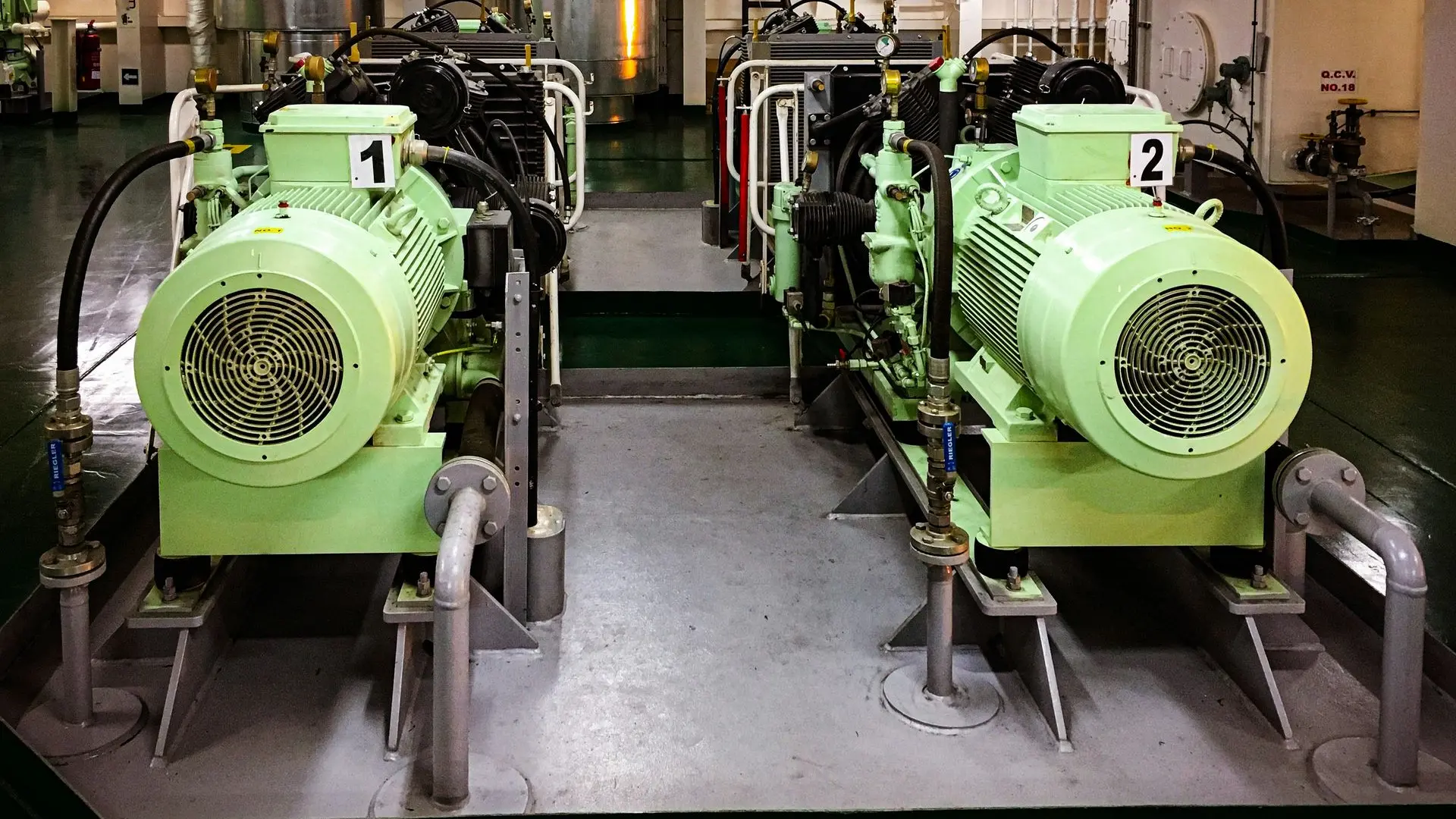

Open slot electric motors

Installed directly in the stator grooves for precise thermal monitoring close to the copper.

Industrial motor manufacturing

Used from assembly to ensure discreet integration without interfering with insulation or winding.

Get an offer

Why choose a notch temperature probe ?

The notch probe is designed for localized thermal monitoring, discreetly and reliably integrated into electric motors. It combines compactness, robustness, and precision without disrupting the internal architecture.

1. Ultra-localized measurement

Positioned directly in the slot, it captures the actual winding temperature, closest to the copper.

2. Discrete and flat format

It's shape allows integration without added thickness, ideal for not interfering with insulation or assembly.

3. Simple installation in manufacturing

It integrates from the winding stage without requiring drilling or mechanical adaptation.

4. Renovation compatible

Suitable for motors under maintenance or rewinding without major modifications.

5. Enhanced reliability

Encapsulated or sheathed, it withstands electrical, thermal, and mechanical stresses.

6. Multi-point thermal control

Allows monitoring of multiple stator points for detailed and preventive heat analysis.